Things about American Plastics

Table of ContentsThe smart Trick of American Plastics That Nobody is DiscussingThe Buzz on American PlasticsNot known Details About American Plastics The Best Strategy To Use For American PlasticsAmerican Plastics Things To Know Before You Get This

A little homework can aid you with time. It is challenging to judge its quality in the beginning look with the appearance of HDPE pipe installation, many problems are exposed when using, so we can only have a correct judgment after usage. Therefore, it is necessary to choose HDPE pipeline fittings made by an expert manufacturer with a great online reputation and online reputation.A technological professional is important for an excellent item, specifically in the manufacturing sector, due to the fact that a little error will cause the failing of the entire task. HDPE pipes can replace concrete pipelines in area systems to conserve time and expense of repairing broken or burst pipes. HDPE pipe is likewise a less costly choice contrasted to other piping products in terms of operating and setup costs.

5 Simple Techniques For American Plastics

HDPE pipelines are produced with strong straight or curved sections. The pipes are not breakable and can be quickly placed into a curved location without additional jointing or welding.

Chemicals immune to HDPE pipelines can pollute the pipe. The pipeline does not function with chemicals and does not melt warm or electrical power.

HDPE pipes are naturally strong and immune to damages brought on by external loads, high stress or vibration - https://zenwriting.net/americanplastics/high-quality-hdpe-pipe-thats-built-to-last. The pipelines can hold up against handling and bend also in cool weather. Safe eye liner HDPE internal tubes Smooth Line Pipe Moving lining making use of roller combinations Pipe explosion Plastic pipes systems Building of brand-new pipelines Rust resistance, no dripping, high durability

Warmth integration, while its difficulties exist, can develop solid and reputable joints. Responses: The strength and durability of HDPE can be determined by its capability to withstand temperature levels of around 248F in the short term or perhaps a consistent 230F. If your application includes gas and liquid to access and increase those temperatures, HPDE piping is a trusted remedy.

The Best Strategy To Use For American Plastics

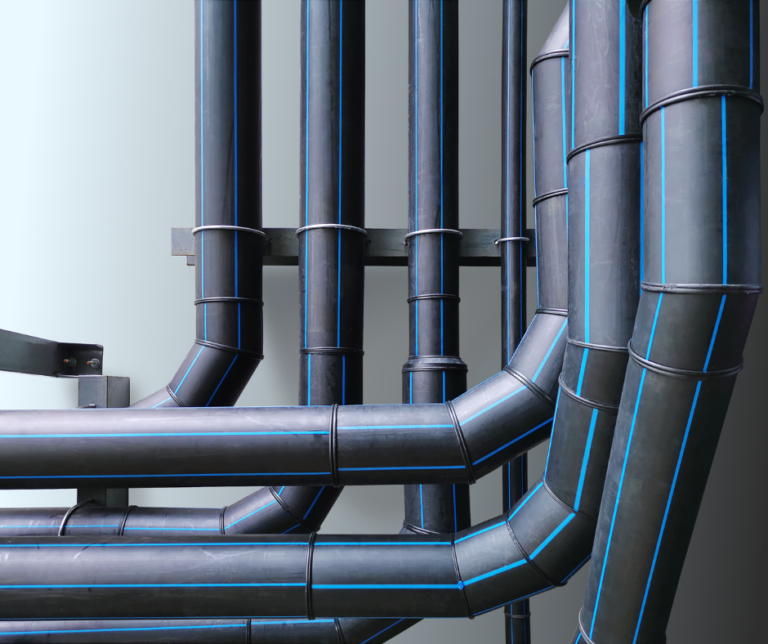

A potable water line/potable water pipeline is always dark with blue red stripes and pipelines passing via liquids, liquids under stress, and procedure gases are constantly filled with a yellow or black coat with yellow lines. HDPE pipe product have actually been made use of in the general industry for over half a century and their results are astonishing, building confidence among makers that they are more focused on HDPE pipe options.

Times considering that 1991 Elimination of resin needs with gauge and change. In the stress fracture resistance examination the cell department needs were damaged. Therefore, it is affordable in conclusion that HDPE pipe constructed today may have.

Each dimension classification is designed remembering the demands of pressure, circulation price, and environmental variables of the designated application. By matching the correct HDPE pipe size to its use, engineers and contractors can maximize performance and prolong the life expectancy of their piping systems. Dimension and size are related ideas in the context of HDPE pipelines.

See This Report on American Plastics

As specified earlier, pipelines with reduced SDR worths have the ability to endure greater pressures, which is an important consideration in the selection procedure for projects that entail high stress or critical applications. hdpe pipe fittings Midland TX. Picking a pipeline with an unacceptable SDR can result in system failure, safety threats, and costly fixings. Picking the proper HDPE pipe dimension is crucial for the success and efficiency of any kind of piping system

Application Specifics: Tailor your pipe size selection to the particular requirements of its application, whether for municipal, industrial, or various other uses. Understanding just how the HDPE pipe will be used, the expected circulation rates and the pressure requirements are vital. As an example, high-pressure applications might call for a pipe with a greater wall surface thickness to stand up to the interior stress and anxieties, while a lower-pressure, high-flow system could prioritize diameter size to lessen rubbing loss.

Excitement About American Plastics

Adhere to these actions: Examine the Application: Establish the pipe's meant usage, consisting of environmental variables and solution problems. Determine Circulation Rates: Use industry-standard calculations or software to estimate the height and standard circulation rates. Understand Pressure Needs: Determine the stress rating needed based on system demands. Describe SDR: Inspect the standard dimension proportion to locate a pipeline that can take care of the needed pressure.

Choosing the appropriate HDPE pipeline size is a delicate equilibrium between various technical specifications and practical demands - https://my-store-10c0e87.creator-spring.com/. However, with cautious factor to consider and exact calculations, you can make certain the size of the pipeline you choose will certainly offer your demands effectively and effectively. Selecting the correct HDPE pipe dimension is vital for system performance, toughness, and cost-effectiveness

Comprehending these aspects will certainly guarantee optimal efficiency and compatibility throughout your piping system - high quality hdpe pipe. The awaited flow price or volume of the fluid being transferred is just one of the key components in pipe dimension selection. A pipeline that is navigate to this website as well small can restrict flow, creating stress loss and potential obstructions, while an extremely huge pipeline may bring about unnecessary expenditure and minimized system effectiveness